Alright, F1 fam, buckle up! Today we’re diving deep into the heart and bones of every Formula 1 car—the suspension and chassis. If you think this is just about “metal bits holding the wheels on,” you’re about to have your mind blown harder than a Red Bull DRS overtake. This is the story of how invisible engineering genius turns raw horsepower into lap records, heartbreak, and glory. And yeah, I’ll sprinkle in some TikTok humor and a few emotional moments—because, let’s be honest, if you’ve ever watched a car dance through Eau Rouge or survive a Monaco shunt, you know this stuff is pure drama.

- The Backbone of a Dream: Chassis as the Soul of F1

- Suspension: The Unsung Hero of Every Lap

- Platform Control: The Secret Sauce of Modern F1

- The Evolution: From Leaf Springs to Carbon Fibre Wizards

- The Human Side: When Engineering Meets Emotion

- Engineering Deep Dive: What Makes F1 Suspension So Special?

- The Setup Game: Where Championships Are Won and Lost

- The Future: What’s Next for F1 Suspension and Chassis?

- #fyp

The Backbone of a Dream: Chassis as the Soul of F1

Let’s start with the chassis. It’s not just a frame—it’s the literal backbone of every F1 car, the thing that holds the dreams (and sometimes the tears) of drivers, engineers, and fans together. Back in the day, F1 cars were built on ladder frames or spaceframes, basically metal Meccano sets with engines strapped on. But then, in 1962, Colin Chapman and Lotus dropped the mic with the Lotus 25—the first monocoque chassis. Suddenly, the car’s body was the structure, not just a shell. It was lighter, stiffer, and safer. The game changed overnight.

Fast forward to today, and the chassis is a carbon fibre masterpiece. We’re talking about a material that’s five times stronger than steel and lighter than your last excuse for skipping leg day. Every team guards their chassis design like it’s the secret recipe for Coca-Cola. Why? Because the tiniest tweak in stiffness, weight distribution, or aerodynamic integration can mean the difference between a podium and a DNF.

The chassis is the backbone of any Formula 1 car, providing the structural support and aerodynamics necessary for speed and performance. — MotorsportEngineer.net

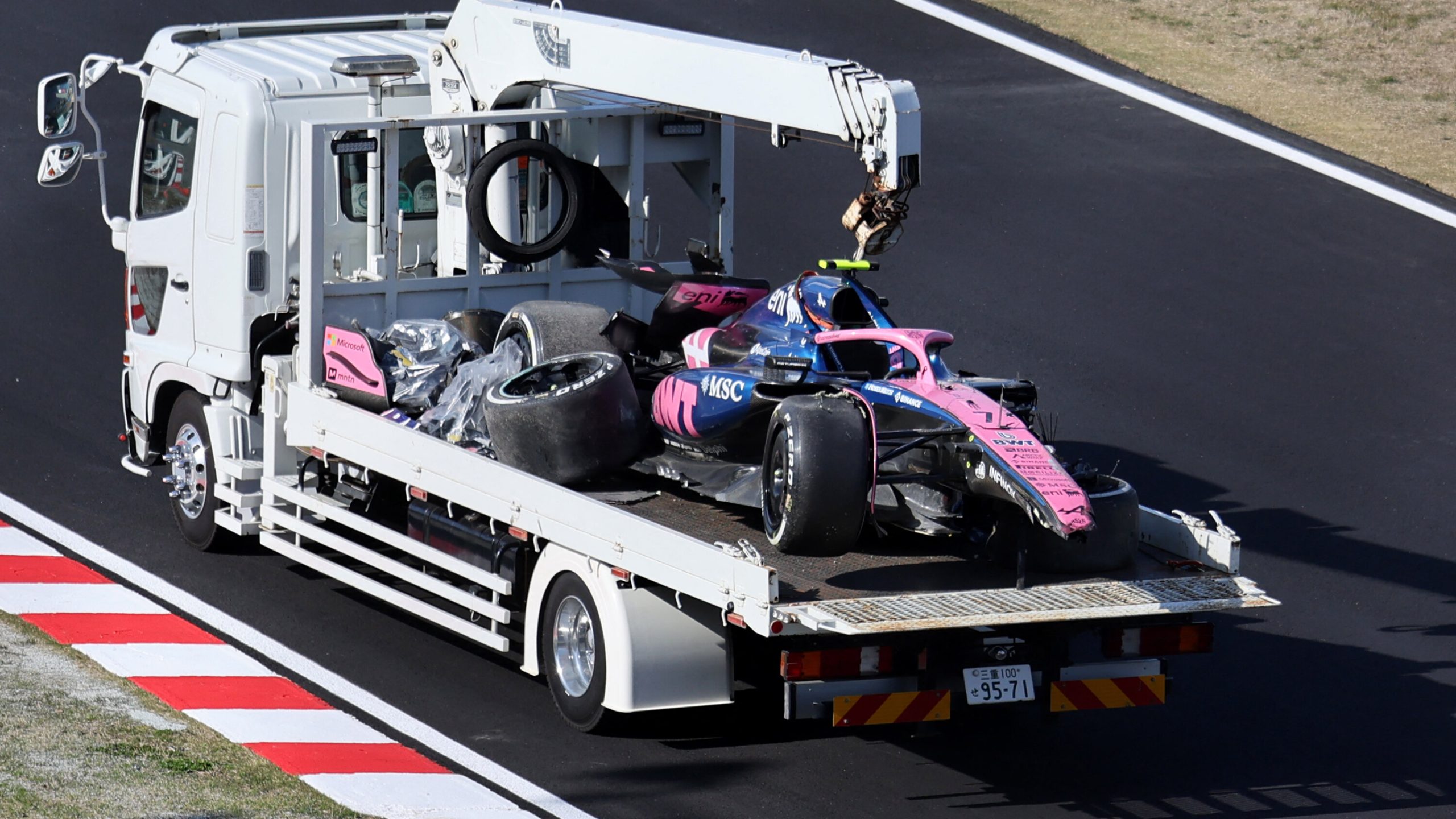

And don’t forget safety. The monocoque is basically a carbon fibre cocoon, designed to keep the driver alive in crashes that would make your PlayStation controller vibrate in sympathy. Remember Grosjean’s Bahrain fireball in 2020? He walked away because of the strength of that chassis.

Suspension: The Unsung Hero of Every Lap

Now, let’s talk suspension. If the chassis is the backbone, the suspension is the nervous system—constantly adapting, reacting, and keeping the car glued to the tarmac. In F1, suspension isn’t about comfort (sorry, Lewis, no massaging seats here). It’s about maximizing grip, controlling aerodynamics, and making sure the car doesn’t yeet itself into the barriers when you hit a kerb at 250 km/h.

The basics? Springs, dampers, anti-roll bars. But in F1, even the springs are wild—torsion bars, heave springs, and even mesh discs that act as “bump stops” under insane aerodynamic loads. The goal? Keep the tyres in perfect contact with the track, no matter how much downforce is squashing the car into the ground.

Check out this awesome breakdown from Driver61, where they get hands-on with Alpine’s 2022 F1 suspension. It’s like an engineering ASMR session:

Watch on YouTube: F1 Suspension Is Simpler Than You Think

The suspension of a Formula One car is a complex system of different elements and plays an important role in getting the set-up right… For the aerodynamic concept to work, the position of the car relative to the track is extremely important. — Mercedes-AMG F1 Team (source)

Platform Control: The Secret Sauce of Modern F1

Here’s where it gets spicy. In modern F1, suspension isn’t just about handling bumps—it’s about “platform control.” That means keeping the car’s ride height, pitch, and roll in the perfect window for maximum aero performance. Raise or lower the car by just a few millimeters, and you can lose massive downforce. That’s why teams obsess over pushrod vs. pullrod setups, inboard vs. outboard springs, and even the shape of the wishbones (which, by the way, have to be strong enough to hold the wheels on in a crash, but thin enough to not mess up the airflow).

The faster an F1 car goes, the more downforce it generates. When it’s travelling at high speeds it can generate an amount of downforce that is several times its body weight. Therefore the suspension has to deal with tonnes of extra load when the car is going fast. — Mercedes-AMG F1 Team

And don’t even get me started on the setup work. Every circuit is different—Monaco’s bumps, Monza’s curbs, Suzuka’s high-speed esses. Teams spend hours in the sim and on the setup sheets, tweaking camber, toe, and damper rates to find that sweet spot between mechanical grip and aerodynamic stability.

The Evolution: From Leaf Springs to Carbon Fibre Wizards

Let’s take a quick trip down memory lane, because F1 suspension and chassis design is a story of relentless innovation:

- 1950s–1960s: Simple double wishbones, leaf springs, and spaceframes. Drivers needed biceps the size of Bottas’ neck to keep these beasts on track.

- 1962: Lotus 25 introduces the monocoque chassis. Suddenly, cars are lighter, stiffer, and safer.

- Late 1960s–1970s: Lotus 49 uses the engine as a stressed member. Ferrari 312T brings in the transverse gearbox for better weight distribution.

- Late 1970s–Early 1980s: Lotus 78/79 invents ground effect. Suspension has to cope with insane downforce.

- 1981: McLaren MP4/1 debuts the carbon fibre monocoque. Safety and performance skyrocket.

- Late 1980s–Early 1990s: Lotus 99T and Williams FW14B bring active suspension—computers controlling ride height in real time. Banned later, but the tech was wild.

- 2000s–2020s: Pushrod and pullrod suspensions, carbon fibre everything, and the rise of platform control.

With the development of aerodynamic downforce aids over the years, the struggle in suspension has developed into one of striking a balance between being stiff enough to manage the immense aero on the straights and being able to corner effectively. — Hagerty Media (source)

The Human Side: When Engineering Meets Emotion

Here’s the thing—behind every suspension arm and carbon fibre tub, there’s a team of engineers pulling all-nighters, drivers giving feedback with their butts (seriously, ask any F1 driver), and fans like us screaming at the TV when a car bounces over a kerb or survives a crash that looks impossible.

Remember when Red Bull’s suspension setup let Max Verstappen fly over the kerbs at Austria, while Ferrari’s stiffer setup left them bouncing like a TikTok dance gone wrong? Or when Mercedes’ “zero pod” chassis in 2022 looked like a spaceship but struggled with porpoising, forcing the team to rethink their entire suspension philosophy?

And don’t forget the heartbreaks—like when a tiny suspension failure cost a driver a championship, or when a chassis tweak turned a midfield car into a race winner overnight. This is the stuff that makes F1 more than just numbers and lap times. It’s about risk, reward, and the relentless pursuit of perfection.

Engineering Deep Dive: What Makes F1 Suspension So Special?

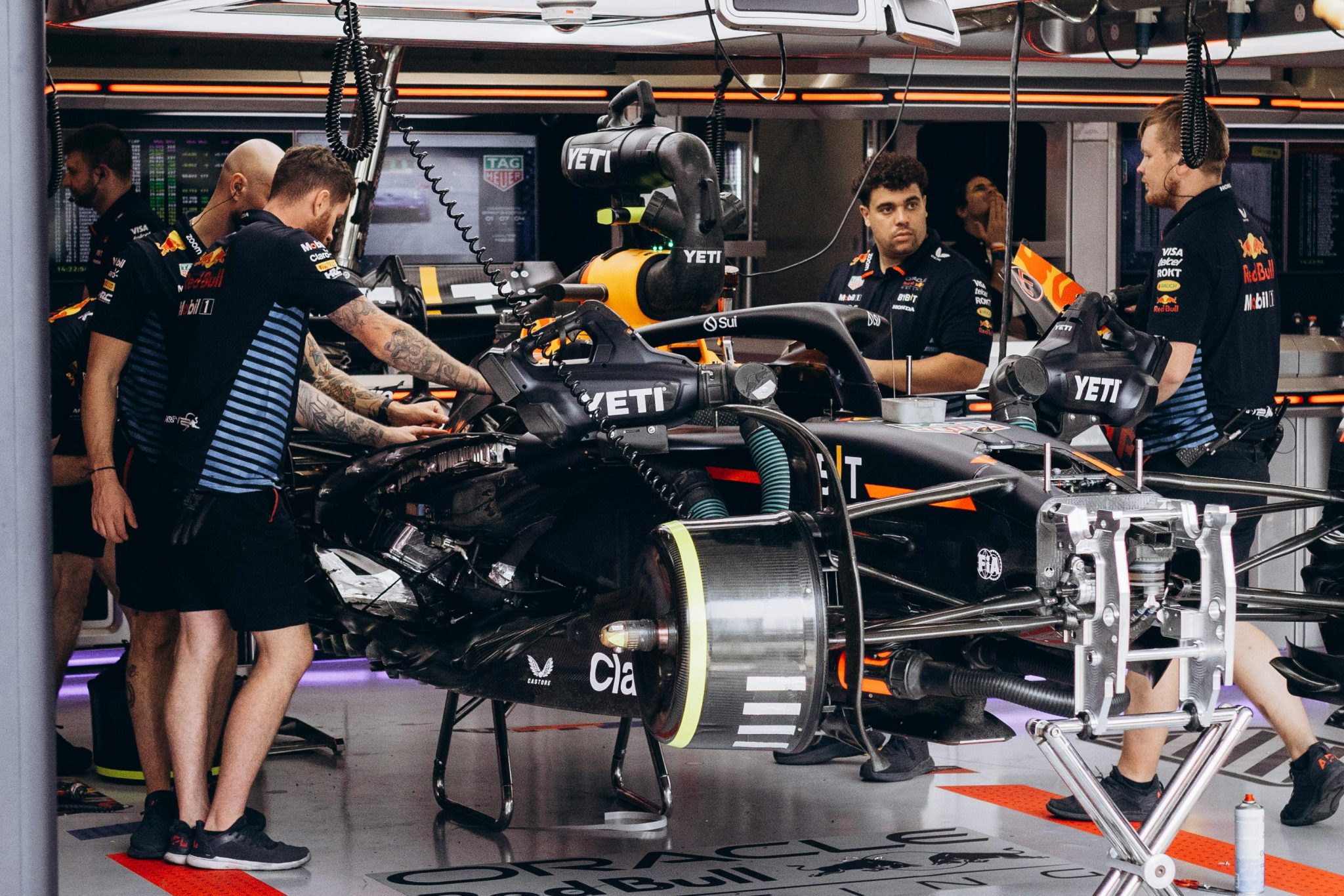

Let’s nerd out for a second. F1 suspension is all about balancing three things: strength, weight, and aerodynamics. The wishbones, pushrods, and pullrods are made from carbon fibre or titanium—strong enough to handle 10,000+ Newtons of force, but light enough to keep the car under the minimum weight limit.

The inboard suspension (hidden under the bodywork) uses gas springs and dampers, all adjustable to the nth degree. Outboard parts (like uprights and axles) are tucked behind the wheels, often inside carbon fibre brake ducts. And every part is designed to minimize drag and maximize airflow to the floor and diffuser.

The suspension needs to be light—just like every other part on an F1 car. Lastly, some suspension elements like the wishbones are out in the airflow, so those elements need to be relatively thin and skinny to reduce their aerodynamic penalty. — Mercedes-AMG F1 Team

And let’s not forget the tyre tethers—three per wheel, hidden inside the wishbones, designed to keep the wheels attached in a crash. Safety and performance, always hand in hand.

The Setup Game: Where Championships Are Won and Lost

Here’s where the magic happens. Every race weekend, teams spend hours tweaking the suspension setup—camber, toe, ride height, damper rates, anti-roll bar stiffness. The goal? Maximize tyre contact patch, optimize platform control, and give the driver a car they can trust at the limit.

A great setup can turn a good car into a race winner. A bad setup? Well, just ask any driver who’s spent a Sunday afternoon wrestling a “diva” car around the track. (Looking at you, 2017 Mercedes W08.)

Optimising the suspension for each circuit is an important part of the general set-up work for an F1 car. Through the suspension set-up, the team can minutely control the way the tyre is presented to the road and optimise handling and grip levels by changing parameters like toe and camber. — Mercedes-AMG F1 Team

The Future: What’s Next for F1 Suspension and Chassis?

With the 2026 regulations looming, everyone’s wondering what the next big leap will be. Will we see new materials, smarter passive suspension systems, or even a return to some form of active control (within the rules, of course)? One thing’s for sure—F1 engineers will keep pushing the limits, finding new ways to turn science fiction into race-winning reality.

And as always, the battle between teams will be fought not just on the track, but in the wind tunnels, CAD workstations, and late-night engineering meetings where the next championship-winning idea is born.

#fyp

Want to go even deeper? Check out these awesome resources and videos:

- F1 Suspension Is Simpler Than You Think – Driver61 YouTube

- From Concept To Track: Chassis Design Engineering In Formula 1 – MotorsportEngineer.net

- The Suspension of a Formula One Car – Mercedes-AMG F1

- Formula 1 Engineers Prove Anything Can Be a Spring – Hagerty Media

- Tech Explained: Chassis – Racecar Engineering

- Understanding The Inner Workings Of Suspension In Formula 1 – MotorsportEngineer.net

And if you want to geek out with other F1 engineering nerds, check out the F1Technical.net forums.

Remember, next time you see a car glide through a corner or survive a monster crash, give a silent nod to the unsung heroes—the engineers, the designers, and the wild suspension and chassis tech that make F1 the greatest show on earth. See you at the next race, legends! 🏁